Achieving Livestock Operation Efficiency: The Role of Stainless Steel Filters in Hog Farms

Questions?

Contact us for more information.

Introduction

The livestock industry, with its vast scale and intricate processes, has always been on the lookout for innovations that can enhance efficiency, reduce costs, and ensure sustainability. One of the significant challenges faced by livestock operations, especially hog farms, is the management of waste. Separating solids from liquids in waste streams is not just essential for environmental compliance but also for the overall health of the livestock and the efficiency of the operation. Enter the stainless steel filter, a robust solution tailored to address this very challenge, especially given the acidic nature of hog waste.

The Challenge of Waste Management in Hog Farms

Hog farms produce a substantial amount of waste. This waste, laden with solids, liquids, and a mix of organic materials, poses a dual challenge. First, the liquid waste, if not treated, can contaminate water sources, leading to environmental concerns. Second, the acidic nature of hog waste can corrode and degrade standard equipment rapidly, leading to frequent replacements and increased operational costs.

Stainless Steel Filters: A Robust Solution

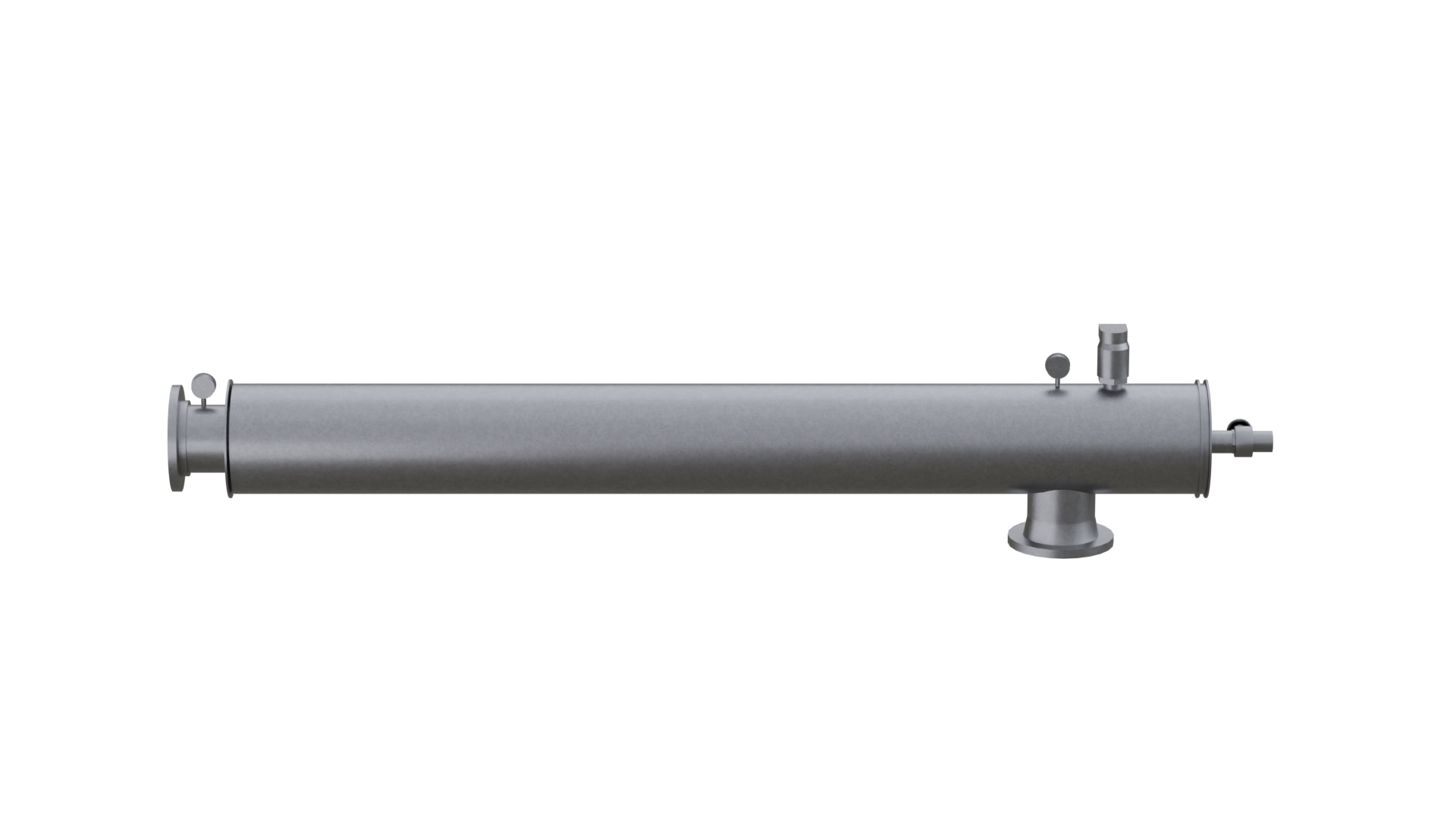

Recognizing the challenges posed by the acidic nature of hog waste, forward-thinking livestock operations have started integrating stainless steel filters into their waste management systems. Stainless steel, known for its corrosion-resistant properties, is particularly suited to handle the acidic waste produced by hogs.

The operation of these filters is straightforward yet highly effective. As the waste is channeled through the system, the stainless steel filter efficiently separates the solids from the liquids. The solids can then be processed further, often used as manure or compost, while the liquids can be treated and safely discharged or reused.

The Transformative Impact

With the integration of stainless steel filters:

Enhanced Durability: Given the corrosion-resistant properties of stainless steel, these filters offer a significantly longer lifespan compared to their non-stainless counterparts. This translates to reduced maintenance and replacement costs for the farm.

Effective Separation: The precision design of these filters ensures that solids are effectively separated from the liquids, allowing for efficient waste processing and reducing the environmental footprint of the farm.

Environmental Compliance: With effective waste separation and treatment, hog farms can ensure they meet environmental regulations, avoiding potential penalties and fostering good community relations.

Operational Efficiency: With a reliable waste management system in place, farms can focus on core operations, ensuring the health and productivity of their livestock.

Conclusion

In the demanding environment of livestock operations, where challenges are aplenty and efficiency is paramount, stainless steel filters emerge as a beacon of innovation. By addressing the critical need for effective waste separation and offering enhanced durability in the face of acidic hog waste, these filters play a pivotal role in ensuring the success and sustainability of hog farms. As the industry continues to evolve, solutions like these not only ensure operational efficiency but also pave the way for environmentally responsible livestock farming.